#Reverse Laminar Airflow

Explore tagged Tumblr posts

Text

0 notes

Text

The Apex of Purity: Brinda Pharma Technologies for Cleanroom Solutions

Brinda Pharma Technologies, based in India, specializes in manufacturing and supplying a comprehensive range of cleanroom equipment for highly regulated industries such as pharmaceuticals, biotechnology, electronics, and healthcare. The company emphasizes its commitment to quality, deep industry knowledge, and adherence to stringent international standards.

Their product portfolio, engineered for maintaining absolute purity and preventing contamination, includes:

Air Showers: Designed as a primary defense at cleanroom entry points to remove surface contamination from personnel and materials.

Pass Boxes (Static & Dynamic): Facilitate contamination-free material transfer between different cleanroom classifications or uncontrolled areas. Dynamic versions include integrated HEPA filters and air showers.

Laminar Air Flow (LAF) Units: Available in vertical, horizontal, and mobile configurations, these units create ultra-clean work zones with continuous, unidirectional HEPA-filtered airflow for sensitive operations.

Reverse Laminar Flow (RLF) Units / Dispensing Booths: Provide containment and protection for personnel and the environment during the dispensing or weighing of hazardous materials by drawing air away from the operator.

Bio Safety Cabinets (BSCs): Offer robust protection for products, personnel, and the environment in laboratories dealing with biological agents, featuring advanced HEPA-filtered airflow and containment principles.

Fan Filter Units (FFUs): Modular units with high-efficiency fans and HEPA/ULPA filters that continuously circulate and filter air to maintain precise cleanroom classifications.

Garment & Storage Cabinets: Specialized cabinets designed for secure and pristine storage of cleanroom attire and sterile items.

De-Dusting Tunnels: Engineered for efficient removal of dust and particulate matter from objects or materials before they enter the cleanroom.

Brinda Pharma Technologies positions itself as a trusted partner for cleanroom solutions, focusing on robust, efficient, and long-lasting equipment. They highlight their dedication to innovation and continuous product evolution to meet the dynamic needs of industries requiring controlled environments.

0 notes

Text

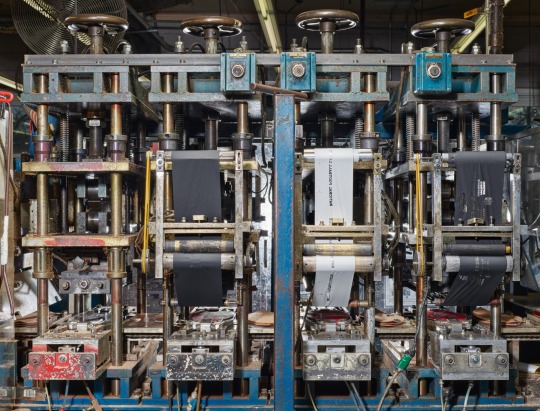

Wilson worker Lindsey Kiene cuts leaf-shaped panels that are tapered at both ends. These will be sewn together to make the iconic oblong shape of the football, a key feature that reduces the ball’s wake and drag.

Step Inside The Factory Where The NFL’s Footballs 🏈 🏈 🏈 Are Made

Few Have Seen Inside Wilson’s Facility where Dozens of Expert Craftspeople Meticulously Put Together a Product Whose Design Hasn’t Changed For About a Century.

— By Terry Ward | Photographs By Christopher Payne | February 9, 2024

What’s more American than cheering as your football team sends a long bomb tightly spiraling toward its end zone target? It’s a tradition that stretches back to the late 19th century.

While today’s “pigskin” is no longer made with the pig’s bladder of football’s late-1800s origins (all pro and collegiate footballs are now constructed from cowhide leather with synthetic rubber interiors), the shape and dimensions of the NFL football have remained the same for roughly 100 years.

Sewn Footballs are sent down this conveyor to the lacing department at the Wilson factory in Ada, Ohio.

Leather arrives every week from the Horween Leather Company in Chicago. The leather is stamped to give it a pebbly feel, and tiny W’s are embossed on the leather to ensure authenticity.

NFL and NFC names are stamped in foil on leather panels before being sewn together.

That the design from a century ago still perfectly suits the needs of today’s sport is a kind of “historical accident,” says Dr. Rabindra Mehta, chief of the experimental aero-physics branch at NASA Ames Research Center. “Compared to a baseball, a football is a more aerodynamic shape by design.”

Footballs are made from four individual panels of leather, leaf shaped and tapered at both ends, which are sewn together inside out. Next, the leather is steamed so that it becomes soft enough to turn right side out. An air bladder is then inserted and the football is laced together by hand.

A football’s shape is not actually a ball in the spherical sense of the word, but a prolate spheroid: oblong, with pointed ends that make it easier to grip. This shape and the way air flows around it helps the football to travel great distances.

The panels move to the stitchers, like Stephen Brownlow here, who sew the panels into halves and then sew the halves together with heavy brown polyester thread to make an inside-out football. Sewing them inside out makes the seam invisible and more durable.

Characteristics of the football’s surface–including the pebbling of the leather, the stitching of the panels, and the laces themselves–also allow airflow to stay attached longer and minimize drag, compared to something spherical like a baseball ⚾️.

Picture a baseball traveling right, with air traveling past, moving left—this would be what’s called laminar flow, where air travels in a regular, smooth path. In a controlled environment (like a wind tunnel) the airflow would go straight left until it meets the ball, where it bends around until it reaches the “far side” of the ball (this point is called the “apex”). Then the air returns to traveling straight left, past the ball, without touching that far side of the ball 🏀 ⚽️ .

When this happens, there’s a pressure difference between the front and back of the sphere which results in drag, the force that slows the ball down as it’s flying through the air. Golf ball manufacturers tackle this on spherical golf balls by dimpling the ball’s surface to help airflow stay attached longer, reducing drag, therefore letting the ball fly farther.

Keaton Miller, a turner, has the strenuous task of turning the ball right side out. To make the job easier, they use a steam box to loosen the leather and a pneumatic hammer to make the pointed ends more pliable before it is reversed forcibly by hand on a metal pole.

Left: The turner finishes by rolling the seams on the pole to flatten them out. An experienced turner can do this in about 30 seconds.

Right: These Wilson GST balls, the official ball of over 180 NCAA programs and 54 high school football state associations, are ready for lacing.

The thin layer of air on the ball’s surface is called a boundary layer, and a turbulent boundary layer creates turbulent flow—where a football’s design shines. Air meeting a football, with its textured surface and curved shape, would flow around the ball, staying attached longer to its surface than it can on a baseball’s. If the air is flowing left (and the ball is moving right) the air will move up, left, and down along the football’s bowed surface.

While the air may not hug a football’s curves all the way across, airflow does remain attached past its apex, resulting in a minimal wake and less drag. On a baseball, the air only makes a connection on half the ball, creating more of a wake and drag.

Drag can be “challenging to predict, particularly in odd-shaped objects like a football,” says Anette (Peko) Hosoi, Pappalardo professor of mechanical engineering at MIT. Drag depends on the shape of the wake, which, in a football, can vary depending on such factors as its orientation through the air, the velocity at which its thrown, and surface roughness.

Left: Nicole Tedrow, a lacer, inserts a polypropylene bladder into the ball and pushes a nipple through a small hole so the ball can be inflated. The lacers use an awl to pull the laces through the holes and close up the football.

Right: The final step is molding. Nearly completed footballs are placed inside a pressurized chamber that molds them to the correct, uniform shape, removing any residual lumps, crinkles, or rough edges, and inflates them to their correct pressure at 12.5 – 13.5 Psi.

Density of the surrounding air–a function of air temperature–also affects the boundary layer of a football and in turn its aerodynamics, Hosoi says.

“Warm air is less dense than cold air. If the air is less dense, there is less drag, so footballs may fly further on warmer days,” she says, adding that the phenomenon has been well documented in baseball, which clocks more home runs during hot and humid weather than the contrary.

A tight, spiraled throw wobbling not at all is indeed a thing of beauty, no matter the weather around it.

”The axis of the spin is aligned with the direction the ball will go,” says Mehta, likening it to the way a bullet flies. ”That’s what the quarterbacks are really good at doing.”

Left: These are the actual footballs that will be used in Super Bowl LVIII. The official balls are waiting to be stamped with the winning team logos pending the outcome of the AFC and NFC Championships, and shipped out early so the teams will be able to practice with them.

Right: These cut brass dies were used to emboss the Super Bowl LV logo in 2020.

#Photography#NFL’s Footballs 🏈 🏈 🏈#Inside Factory#Wilson’s Facility#Expert#Craftspeople#Meticulous Craftsmanship#Unchanged#Terry Ward

1 note

·

View note

Text

Importance of Laboratory Fume Hoods

What are Fume Hoods?

Fume hoods are important laboratory equipment or chamber devices that prevent harmful air from spreading outside of the chamber. The use of these hoods depends on the procedures performed within the laboratory space, safety needs, protection of specimens/content, experiment size, and the type of fumes to contain. The term is a name given to devices that work on the same fume containment principle depending on the content in use. Devices like Laminar Fume Hoods, Pass Box, Laminar Air Flow etc. all fall in the same category of laboratory equipments.

Main Uses of Fume Hoods

The most important use of a fume hood is discharging waste present in the air of a laboratory or an area where an experiment using content that emits harmful fumes. In a laboratory setting, tests contain various materials like chemicals, gases, odour, corrosive or flammable items. All these items, in some way, emit fumes that contaminate the air for handlers and personnel present in a lab. In order to prevent pollutants from spreading and protect the operators, these hoods are used in the area near the experiment.

Purpose of Lab Fume Hoods

The purpose of lab fume hoods is to provide a ventilated, safe and comfortable experimental environment for the laboratory. That is to say, laboratory ventilation is to solve the problems of the physical health and labour safety of experimental operators. At this time, the laboratory must have a sufficient number of lab fume hoods to meet the laboratory ventilation, and the supplementary air of the laboratory is provided by the laboratory air conditioning system.

The Role of Lab Fume Hoods

The function of lab fume hoods is to exhaust. According to the experimental products and experimental area of different laboratories, according to the exhaust air volume, different air volumes and different numbers of lab fume hoods are designed to meet the operational needs of the laboratory. Especially in special laboratories such as chemical testing laboratories and chemical laboratories, because the experimental operation process will produce toxic, harmful, flammable, and explosive gases. To prevent the diffusion of these gases, many laboratory construction companies will arrange lab fume hoods around the pollution sources. Obviously, this kind of operation is a routine operation. With the development of science and technology and the continuous upgrading of lab fume hoods, the fume hoods already have the function of experimental operations, which is to transfer the experiments that are usually performed on the test bench to the fume hood for operation. The lab fume hood is more rigorous and ensures harmful gases can be discharged in a centralized manner to protect the safety of experimental operators. Besides, the operation is more convenient and fast, which is also the main function of the laboratory fume hood.

Functions of Lab Fume Hoods

The lab fume hood has a release function, which can concentrate and dilute the harmful and toxic gases generated in the experiment inside the lab fume hood, and then discharge them outside. This is the release function of lab fume hoods. Will the toxic gas released from the fume hood flow back? This involves another function of the fume hood, the non-backflow function. The gas generated by the experiment inside the lab fume hood is generated by the airflow generated by the exhaust fan, and the harmful gas is not reversed from the inside of the fume hood. It is an indoor function. For this non-backflow function, Swastik has a special operation method for the connection between the lab fume hood and the ventilator. The lab fume hood also has another main function – the isolation function, which is reflected in the glass in front of the ventilation that separates the inside and outside of the fume hood. The lab fume hood also has the function of supplementary function and control of wind speed.

In a brief summary, the main functions of the laboratory fume hood are the release function, non-backflow function, isolation function, wind speed control function, and so on.

1. Release function: It should have a mechanism to absorb the harmful gas generated inside the lab fume hood by absorbing the gas outside the hood, diluting it, and then discharging it outside.

2. Non-backflow function: It should have the function of preventing harmful gas from flowing back into the room from the inside of the fume hood by the airflow generated by the exhaust fan inside the fume hood. In order to ensure the realization of this function, it is the best way to connect a fume hood and a ventilator with a single pipe. It cannot be connected with a single pipe, and it is limited to parallel connections in the same room on the same floor. Installed at the end of the pipe (or at the top of the floor).

3. Isolation function: There should be a non-sliding glass window in front of the fume hood to separate the inside and outside of the fume hood.

4. Supplementary function: there should be a channel or alternative device for sucking air from outside the fume hood when discharging harmful gases.

5. Wind speed control function: In order to prevent harmful gases from escaping in the fume hood, a certain suction speed is required.

6. Heat resistance and acid and alkali corrosion resistance: some fume hoods need to be equipped with electric furnaces and some experiments produce a large amount of acid and alkali and other toxic and harmful gases, which are extremely corrosive.

1 note

·

View note

Text

Buy Perfectly Designed Distilled Water Plant from Indian Manufacturers for your Plant

Are you in need of a distilled water plant? It is an essential component for pharmaceutical industries and other similar industries. There are a lot of advantages when you buy it from the Indian manufacturers. The most striking advantage is their quality. Indian manufacturers of zero hold up filter press are known for the quality of their products. Again, all their products are available online. If you have a smartphone or laptop connected to the internet, you can order their products within a matter of few seconds. When we decide to buy a static pass box, we should purchase it from a reliable manufacturer. When you buy these products from reliable manufacturers in India, you can use them without any error for a long time.

Reliable Self Cleaning Filter Suppliers

A lot of industries, including pharmaceutical plants require a self-cleaning filter. These filters are available from reliable manufacturers and suppliers in India. All manufacturers sell their products online and you can order the products you want at any time. Most importantly, you can order it from the comfort of your home or office. When you locate a supplier, you should go through the product descriptions they have displayed on their company websites. When you search for a bag filter manufacturer, you may come across several reputed ones. Hence, the ultimate question is how to decide who is the best manufacturer. We can say that a manufacturer adhering to all the quality standards is the best cartridge filter housing manufacturer. Every reliable manufacturer will provide clear details about all their products with the date of manufacturing and date.

The Best Multi Cartridge Filter Manufacturer

You are reading this article because you have been searching for the best multi-cartridge filter manufacturer. All the best manufacturers and suppliers use quality raw materials to produce standard products. Most of these manufacturers make use of stainless steel and epoxy steel to manufacture the inner and outer parts of their products. Hence, you can be sure that these products will last for a long time. You can also buy reverse laminar airflow for your production plant. Search online for a reputed supplier. This is the best way to locate a reliable supplier. You can also consult your peers and friends to know their experience with the manufacturer you choose to buy products.

#distilled water plant#zero hold up filter press#static pass box#self-cleaning filter#bag filter manufacturer#cartridge filter housing#multi-cartridge filter#reverse laminar airflow

0 notes

Text

https://pureairsystemchennai.com/

We are leading manufacturers of Reverse Flow Laminar Airflow in Chennai and supplying to all over India. Manufactured using the best quality of raw materials in Chennai.

0 notes

Link

Protect your working personnel from airborne contaminants with reverse laminar airflow dispensing booth manufactured by Alpha Linear, Bangalore, best in town.

Visit:- https://www.alphalinear.co.in/equipment/reverse-laminar-airflow-booth/

0 notes

Photo

Aviation Taking Vital Steps

Always at the leading edge of technology, both the space and aviation communities are where you watch to understand how the world is changing—and changing fast.

A friend recently reported in aviation insider magazines that people are doubtful that electrification will work. He explained they are wrong. Electrification is already in testing by all the major aviation companies for flights between 30 and 300 miles. Vertical take-off and some then trimmed to normal flight, demonstrators are showing increasingly surprising economic results. Of course, part of the issue will trickle down to problems for users. Take one example: Where do you land in a city? On top of buildings? Then you better redesign the elevator shafts to allow passengers to get to the roof. And a great deal of electrification of air flight might be pilotless, drones, or UAVs... and the FAA is desperately worried at the proliferation of multiple mid-air converging flights.

Meanwhile, making the next generation of commercial aircraft more efficient and more commercially viable, Boeing have three demonstrator aircraft that they are retrofitting with all sorts of test equipment and modification. One test is for little vanes that emerge, pop up, from the center of the wing at low speeds to improve laminar airflow—allowing a more controllable aircraft at a slower speed, more efficient at low altitude. Similarly they have programs to test laminar-flow winglets, ceramic matrix composite nozzles for engines, touch-screen cockpit displays, active-flow-control vertical tail and wing sections coated with insect repellant, biofuels, advanced sensors, special paint to reduce drag, compact thrust reversers, and a host of other invention. Where are these inventions coming from? Boeing is inviting vendors and other scientists to have a go on their demonstrator, principally a 777-200ER currently flying to Scotland, Frankfurt and back to Seattle. One exciting test involves an intelligent ultraviolet-light-sanitizing system to help clean and sterilize the plane after each landing. An intelligent cabin system is currently in flight—sensors keep track of everything used, from armrests, seatbelts, dirty carpets, galley equipment use... and those sensors will update an AI computer on board the plane of what, where, and when an component needs repair or replacing.

Last, but not least, the military have evaluated all their global installations that are vulnerable to climate related emergencies. The military are not climate change deniers, far from it, they are in lock-step with the scientists knowing there is real danger. The findings they recently posted? The Air Force have 36 bases of which 20 are currently vulnerable with 25 expected to be vulnerable as climate effects gather impact. So the AF number is 20/25 for flooding. For drought? 20/22. For Desertification? 4/5. For wildfires? 32/32. The Army? Flooding 15/17. Drought 5/5, Desertification? 2/2. Wildfires? 4/5. Thawing Permafrost? 1/2. So much for climate change deniers, let them try and dissuade the military who are aware of the real science and danger.

0 notes

Text

Learn about superior Laminar Air Flow Units and Systems made to keep spaces free of contaminants. Explore Innovative Pharmatech's Reverse Laminar Airflow solutions designed for industrial, laboratory, and cleanroom settings. Visit us at https://www.innovativeppl.com/reverse-laminar-air-flow.html or +91 9824243397 for more details.

#Reverse Laminar Air Flow#Laminar Air Flow Unit#Laminar Air Flow System#Reverse Laminar Flow Unit#Reverse Laminar Airflow

0 notes

Text

Brinda Pharma Technologies – Your Partner in Cleanroom Excellence

In today's highly regulated industries, from pharmaceuticals and biotechnology to electronics and healthcare, the demand for meticulously controlled environments is paramount. At Brinda Pharma Technologies, we understand that maintaining absolute purity and preventing contamination are not just goals, but fundamental necessities for the success and safety of your operations.

As a leading Indian manufacturer and supplier of cleanroom equipment, Brinda Pharma Technologies is dedicated to providing cutting-edge solutions that meet the most stringent international standards. We pride ourselves on our deep industry knowledge, commitment to quality, and ability to deliver equipment that forms the very backbone of a compliant and efficient cleanroom facility.

The Brinda Pharma Technologies Advantage: Precision-Engineered for Purity

Our comprehensive range of cleanroom equipment is designed with one core purpose: to create and sustain environments free from particulate matter, airborne microbes, and chemical vapors. We leverage advanced manufacturing techniques and a meticulous approach to ensure every piece of equipment delivers superior performance and unwavering reliability.

Here's a glimpse into the essential products we engineer to elevate your operational purity:

Air Shower: Our state-of-the-art air showers are the first line of defense at your cleanroom entry points. They effectively remove surface contamination from personnel and materials, ensuring that only clean elements enter your controlled environment.

Pass Box (Static & Dynamic): Facilitating seamless and contamination-free material transfer, our pass boxes are indispensable. Whether you choose our static models or the enhanced dynamic versions with integrated HEPA filters and air showers, you can trust Brinda Pharma to prevent cross-contamination between different cleanroom classifications or from uncontrolled areas.

Laminar Air Flow (LAF) Units: We specialize in producing a variety of Laminar Air Flow (LAF) units, including vertical, horizontal, and mobile configurations. These units create an ultra-clean work zone by providing a continuous, unidirectional flow of HEPA-filtered air, essential for sensitive operations where product protection is critical.

Reverse Laminar Flow (RLF) Units / Dispensing Booths: Designed for optimal containment, our Reverse Laminar Flow units, also known as Dispensing Booths, are crucial for protecting both personnel and the surrounding environment during dispensing or weighing of hazardous materials. They achieve this by expertly drawing air away from the operator, ensuring safety.

Bio Safety Cabinets (BSCs): For laboratories and pharmaceutical facilities dealing with biological agents, our Bio Safety Cabinets offer robust protection for the product, personnel, and the environment. We engineer these cabinets with advanced HEPA-filtered airflow and containment principles to ensure maximum safety.

Fan Filter Units (FFUs): As fundamental components for maintaining precise cleanroom classifications, our Fan Filter Units continuously circulate and filter air within your cleanroom space. These modular units integrate high-efficiency fans with HEPA/ULPA filters for consistent air purity.

Garment & Storage Cabinets: Proper storage is key to preventing contamination. Our specialized garment and storage cabinets are designed to securely house cleanroom attire and other sterile items, ensuring they remain pristine until use.

De-Dusting Tunnels: For thorough pre-entry cleaning, our de-dusting tunnels are engineered to efficiently remove dust and particulate matter from objects or materials before they enter your cleanroom, contributing to overall environmental cleanliness.

Your Trusted Partner for Cleanroom Solutions

At Brinda Pharma Technologies, we are more than just manufacturers; we are your dedicated partners in achieving cleanroom excellence. We understand the critical nature of your operations and offer solutions that are not only compliant but also robust, efficient, and built to last. Our commitment to innovation means we are constantly evolving our product range to meet the dynamic needs of industries relying on controlled environments.

When you choose Brinda Pharma Technologies, you choose a legacy of quality, a commitment to precision, and a partner dedicated to elevating the purity and safety of your critical processes. Contact us today to discuss how we can help you build and maintain a world-class cleanroom facility.

0 notes

Text

Importance of Laboratory Fume Hoods

What are Fume Hoods?

Fume hoods are important laboratory equipment or chamber devices that prevent harmful air from spreading outside of the chamber. The use of these hoods depends on the procedures performed within the laboratory space, safety needs, protection of specimens/content, experiment size, and the type of fumes to contain. The term is a name given to devices that work on the same fume containment principle depending on the content in use. Devices like Laminar Fume Hoods, Pass Box, Laminar Air Flow etc. all fall in the same category of laboratory equipments.

Main Uses of Fume Hoods

The most important use of a fume hood is discharging waste present in the air of a laboratory or an area where an experiment using content that emits harmful fumes. In a laboratory setting, tests contain various materials like chemicals, gases, odour, corrosive or flammable items. All these items, in some way, emit fumes that contaminate the air for handlers and personnel present in a lab. In order to prevent pollutants from spreading and protect the operators, these hoods are used in the area near the experiment.

Purpose of Lab Fume Hoods

The purpose of lab fume hoods is to provide a ventilated, safe and comfortable experimental environment for the laboratory. That is to say, laboratory ventilation is to solve the problems of the physical health and labour safety of experimental operators. At this time, the laboratory must have a sufficient number of lab fume hoods to meet the laboratory ventilation, and the supplementary air of the laboratory is provided by the laboratory air conditioning system.

The Role of Lab Fume Hoods

The function of lab fume hoods is to exhaust. According to the experimental products and experimental area of different laboratories, according to the exhaust air volume, different air volumes and different numbers of lab fume hoods are designed to meet the operational needs of the laboratory. Especially in special laboratories such as chemical testing laboratories and chemical laboratories, because the experimental operation process will produce toxic, harmful, flammable, and explosive gases. To prevent the diffusion of these gases, many laboratory construction companies will arrange lab fume hoods around the pollution sources. Obviously, this kind of operation is a routine operation. With the development of science and technology and the continuous upgrading of lab fume hoods, the fume hoods already have the function of experimental operations, which is to transfer the experiments that are usually performed on the test bench to the fume hood for operation. The lab fume hood is more rigorous and ensures harmful gases can be discharged in a centralized manner to protect the safety of experimental operators. Besides, the operation is more convenient and fast, which is also the main function of the laboratory fume hood.

Functions of Lab Fume Hoods

The lab fume hood has a release function, which can concentrate and dilute the harmful and toxic gases generated in the experiment inside the lab fume hood, and then discharge them outside. This is the release function of lab fume hoods. Will the toxic gas released from the fume hood flow back? This involves another function of the fume hood, the non-backflow function. The gas generated by the experiment inside the lab fume hood is generated by the airflow generated by the exhaust fan, and the harmful gas is not reversed from the inside of the fume hood. It is an indoor function. For this non-backflow function, Swastik has a special operation method for the connection between the lab fume hood and the ventilator. The lab fume hood also has another main function – the isolation function, which is reflected in the glass in front of the ventilation that separates the inside and outside of the fume hood. The lab fume hood also has the function of supplementary function and control of wind speed.

In a brief summary, the main functions of the laboratory fume hood are the release function, non-backflow function, isolation function, wind speed control function, and so on.

1. Release function: It should have a mechanism to absorb the harmful gas generated inside the lab fume hood by absorbing the gas outside the hood, diluting it, and then discharging it outside.

2. Non-backflow function: It should have the function of preventing harmful gas from flowing back into the room from the inside of the fume hood by the airflow generated by the exhaust fan inside the fume hood. In order to ensure the realization of this function, it is the best way to connect a fume hood and a ventilator with a single pipe. It cannot be connected with a single pipe, and it is limited to parallel connections in the same room on the same floor. Installed at the end of the pipe (or at the top of the floor).

3. Isolation function: There should be a non-sliding glass window in front of the fume hood to separate the inside and outside of the fume hood.

4. Supplementary function: there should be a channel or alternative device for sucking air from outside the fume hood when discharging harmful gases.

5. Wind speed control function: In order to prevent harmful gases from escaping in the fume hood, a certain suction speed is required.

6. Heat resistance and acid and alkali corrosion resistance: some fume hoods need to be equipped with electric furnaces and some experiments produce a large amount of acid and alkali and other toxic and harmful gases, which are extremely corrosive.

1 note

·

View note

Photo

Protect your working personnel from airborne contaminants with reverse laminar airflow dispensing booth manufactured by Alpha Linear, Bangalore, best in town.

Visit:- https://www.alphalinear.co.in/equipment/reverse-laminar-airflow-booth/

0 notes